Surface and Internal Defect Testing :

Ultrasonic Testing of Cast Ingots.

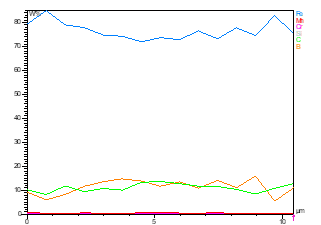

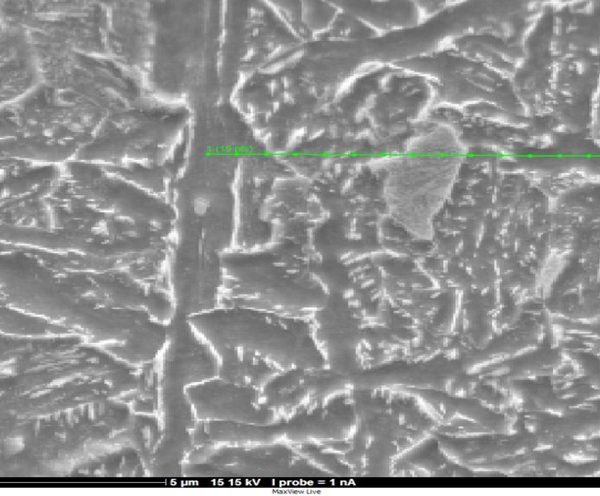

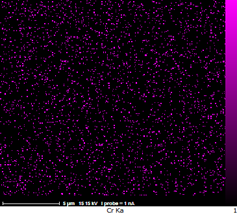

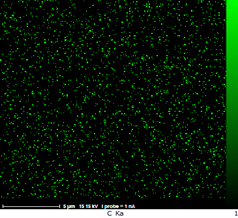

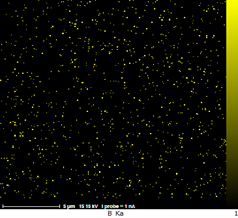

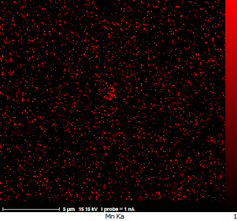

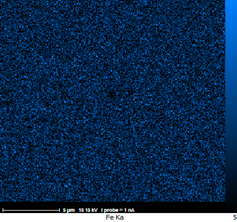

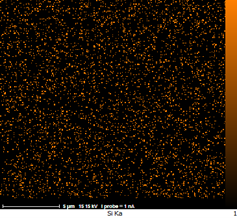

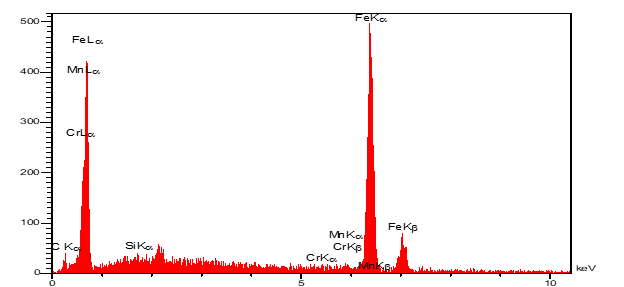

Line Scan Testing :

Linear scanning of steel samples provides precise information on the distribution of elements within the microscopic structure. This technique helps identify small anomalies that may affect the final mechanical properties and ensures uniform composition across the entire product.

These tests play a crucial role in evaluating the mechanical properties of steel, including wear resistance, impact resistance, and surface uniformity assessment. Precise evaluation of physical properties using this method enables quality control and continuous product improvement.

B |

Cr |

Mn |

Si |

C |

Code |

|

|

0.270 |

0.421 |

0.223 |

0.173 |

B1 |

0.001 |

0.270 |

1.011 |

0.316 |

0.291 |

A2 |

0.003 |

0.397 |

0.995 |

0.255 |

0.305 |

A1 |

0.004 |

0.301 |

0.983 |

0.336 |

0.329 |

B2 |

Boron is a strong carbide and nitride-forming element that enhances the strength of tempered and quenched low-carbon steels through martensite formation and precipitation strengthening of ferrite. Carbon steels containing boron serve as a cost-effective alternative to high-carbon and low-alloy steels. Low-carbon boron steels exhibit better cold deformability and, through heat treatment, can be transformed into steels with equivalent hardness but higher toughness for a wide range of applications such as tools, machine components, and fasteners.

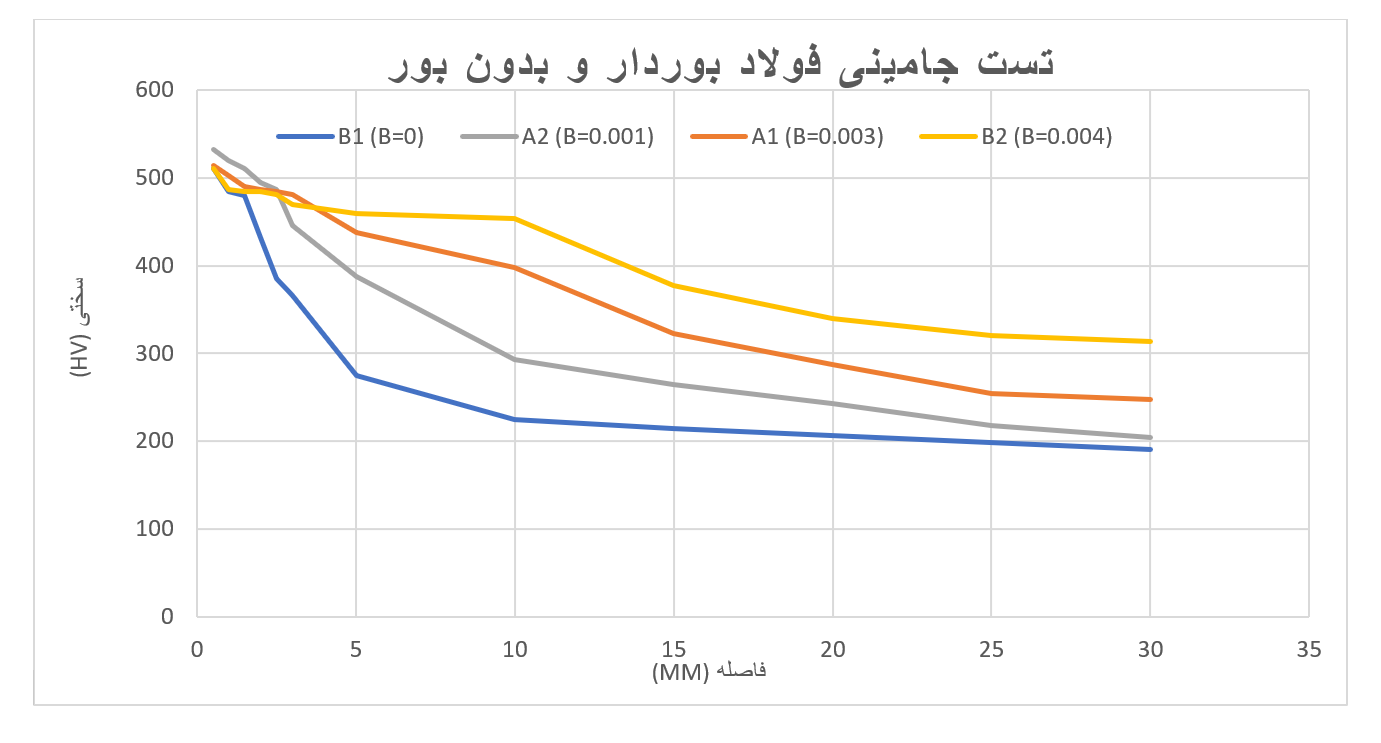

The figure below shows the hardenability graph of the low-alloy boron-containing steel 30Mnb4 compared to boron-free steel (without boron – boron 0.001 – boron 0.003 – boron 0.004). Adding 0.004% boron to steel containing 0.3% carbon, 1% manganese, and 0.4% chromium increases hardness by approximately 64% at a greater depth compared to a sample with the same composition but without boron. As indicated in the graph, there is no difference in surface hardness between boron-containing steel and boron-free steel. Therefore, the initial hardness is not due to boron but rather stems from the martensitic structure, which depends on carbon content. Thus, the effect of boron on hardness enhancement is only observed beneath the surface.

Distance (mm) |

B1 (B=0) |

A2 (B=0.001) |

A1 (B=0.003) |

B2 (B=0.004) |

0.5 |

511 |

532 |

514 |

511 |

1 |

484 |

520 |

502 |

487 |

1.5 |

480 |

510 |

490 |

484 |

2 |

432 |

495 |

487 |

484 |

2.5 |

385 |

487 |

484 |

481 |

3 |

366 |

446 |

481 |

470 |

5 |

275 |

387 |

438 |

459 |

10 |

225 |

293 |

398 |

454 |

15 |

214 |

265 |

323 |

377 |

20 |

206 |

243 |

287 |

340 |

25 |

198 |

218 |

254 |

320 |

30 |

191 |

204 |

248 |

313 |

Hardness (HV).

XRF Test :

Precise determination of the chemical composition of products through XRF, particularly in measuring trace alloying elements such as boron, enables accurate control over chemical formulations. These data play a key role in optimizing formulations and ensuring compliance with required standards.

Elt |

Line |

Int |

Error |

K |

Kr |

W% |

A% |

ZAF |

Formula |

Ox% |

Pk/Bg |

Class |

LConf |

HConf |

Cat# |

B |

Ka |

3.4 |

1.1518 |

0.0338 |

0.0253 |

13.62 |

35.87 |

0.1860 |

0.00 |

4.78 |

A |

9.04 |

18.19 |

0.00 |

|

C |

Ka |

17.0 |

1.1518 |

0.0279 |

0.0209 |

10.73 |

25.45 |

0.1948 |

0.00 |

5.55 |

A |

9.11 |

12.36 |

0.00 |

|

Si |

Ka |

5.6 |

0.3787 |

0.0017 |

0.0012 |

0.18 |

0.18 |

0.6876 |

0.00 |

2.18 |

B |

0.13 |

0.23 |

0.00 |

|

Cr |

Ka |

3.4 |

0.4996 |

0.0033 |

0.0025 |

0.21 |

0.11 |

1.1878 |

0.00 |

2.17 |

B |

0.14 |

0.28 |

0.00 |

|

Mn |

Ka |

5.1 |

0.4996 |

0.0060 |

0.0045 |

0.47 |

0.24 |

0.9572 |

0.00 |

2.31 |

B |

0.34 |

0.60 |

0.00 |

|

Fe |

Ka |

655.4 |

0.4996 |

0.9274 |

0.6960 |

74.79 |

38.14 |

0.9306 |

0.00 |

45.15 |

A |

72.97 |

76.61 |

0.00 |

|

1.0000 |

0.7505 |

100.00 |

100.00 |

0.00 |

0.00 |

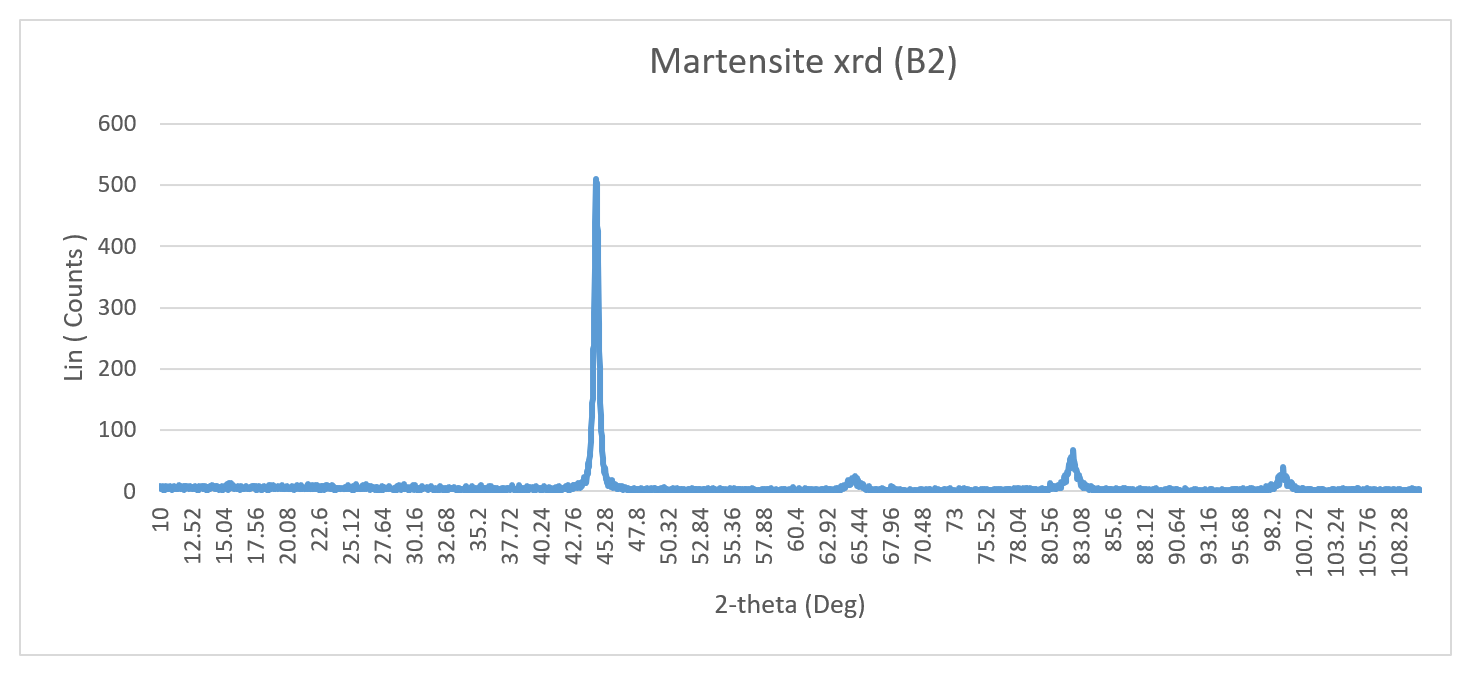

Crystal structure analysis of steel using XRD provides valuable insights into phase distribution and crystalline composition. This method significantly aids in accurately identifying structural changes and ensuring structural stability throughout the production process.

Leveraging Scientific Expertise and the Research and Development Team.

One of the key factors in the success of Azar Nahamain Poulad Sharq Company is its reliance on specialized teams in the fields of metallurgy and research and development. These teams, by utilizing the latest scientific achievements and cutting-edge technologies, conduct precise analyses of test results and play a fundamental role in improving production processes. The continuous interaction between research, development, and production units ensures that any potential defects are quickly identified and corrected, ultimately delivering a final product that meets the technical and quality demands of international markets.

Achievements in the Production of Boron Micro-Alloy Steel.

Using advanced technologies and the accumulated expertise of specialists, Azar Nahamain Poulad Sharq Company has successfully enhanced the production process of boron micro-alloy steel to a level that enables global market competitiveness. This type of steel, with its optimized composition and outstanding mechanical properties, is widely used in industries such as construction, automotive manufacturing, and heavy machinery production. Precise standardization, continuous quality control, and the application of advanced scientific testing are key factors ensuring the credibility and international acceptance of this product.

Azar Nahamain Poulad Sharq Company’s continuous efforts to align with scientific advancements and modern technologies have facilitated access to steel products that meet the highest global standards. Utilizing Jominy tests, XRD, XRF, and Line Scan, combined with close collaboration among specialized teams, has not only ensured product quality but also positioned the company on the path of sustainable development and strengthened competitiveness in the international market. These achievements exemplify the synergy between science and industry in driving innovation and continuous improvement in steel production processes.

This innovative and scientific approach has not only strengthened the company’s position in the domestic market but has also opened new horizons in the steel industry at both the regional and global levels for Azar Nahamain Poulad Sharq. In the future, with the expansion of scientific collaborations and modern technologies, further achievements in the improvement and development of steel products are expected, reinforcing the company’s role as a successful model of integrating science and industry.